Intralogistics Automation

Our Services

Specialized services in design, construction, integration, assembly, support and maintenance of intralogistics automation solutions from global leaders in equipment manufacturing.

Process design and optimization. Simulations. Plant layout.

Manufacturing and Testing. Crucial stages in development.

Project Management PMO. Software Integration.

Installation & Local Assembly. Start-up.

Preventive Maintenance &

Local Corrective Maintenance.

Continuous Support.

Mechanicatronics, electrical and software.

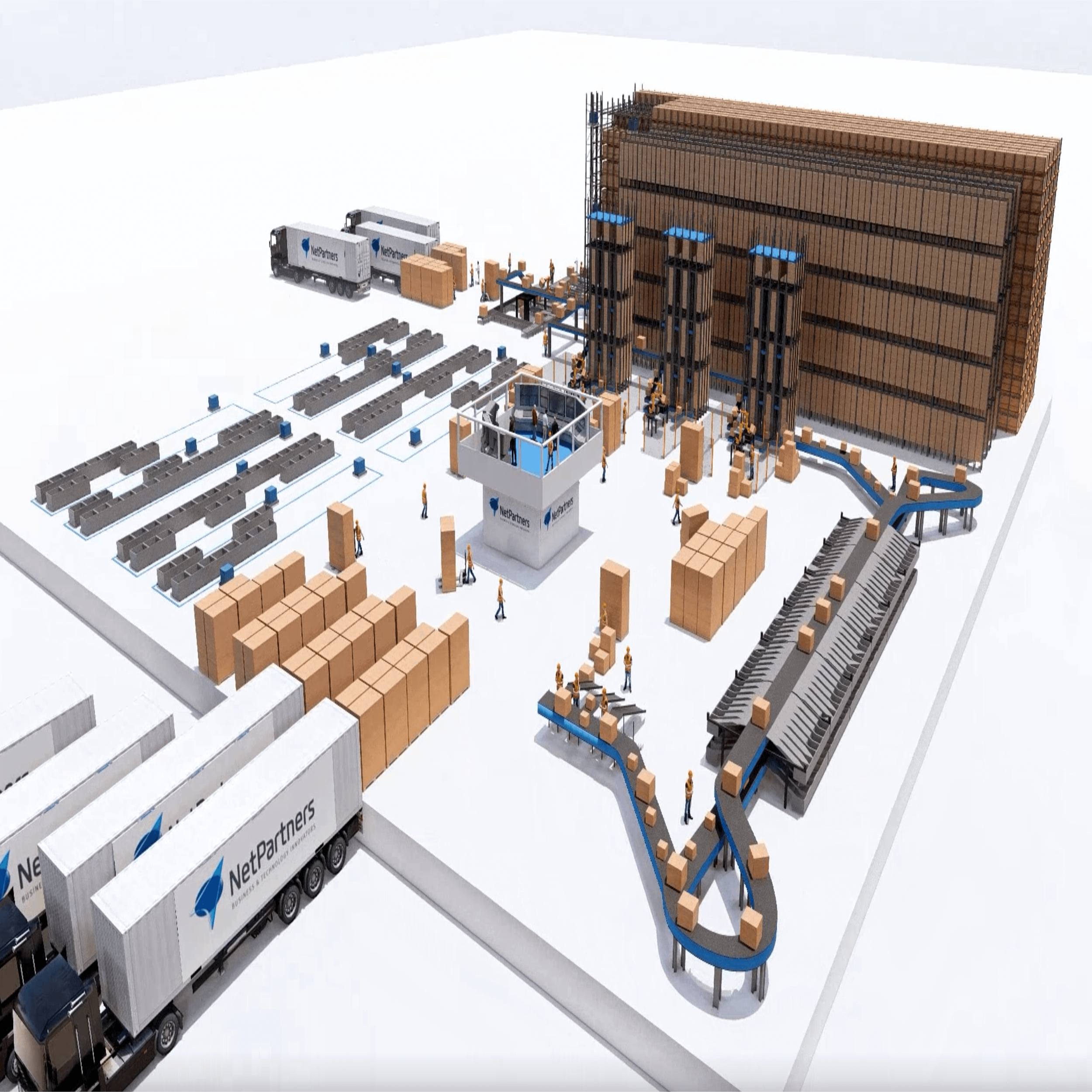

Our Solutions

-

Conveyors

-

PTL Systems

-

Sorters

-

Robotic Arms and AMR's

-

Automated Warehouses & Pallet Shuttles

We implement turnkey projects in alliance with leading companies in engineering, design and construction of solutions for Intralogistics Automation in Spain and Europe.

ISO 9001 Quality Standard for the design and manufacture of automation projects in intralogistics.

Support & Maintenance Centers

Peru

Installations and Maintenance Local and Central Remote Support Latin America.

Colombia

Central de Instalaciones y Mantenimiento Andino, Central America and Mexico.

Chile

Central de Instalaciones y Mantenimiento Sur, Chile, Argentina, Uruguay

We work with Leading Brand Teams

-

Engines

World leading manufacturers have specific motors for energy-efficient conveyor applications.

-

Control

The main control brands on the market have specific control functions for the calibration and operation of robots in applications.

-

Computing

HP-branded servers and peripherals for IT integration and operator interfaces.

-

Rollers

High quality brand in motorized rollers, diverters and intelligent conveyor circuits.

-

Enclosure

Application-specific fences and access gates, with individual access to each elevator, with the highest level of security.

-

Sensors

Detectors and specific peripherals for intralogistics applications.

Success Stories

INTRALOGISTICS AUTOMATION

An intralogistics automation line was implemented in the warehouses in Peru and Colombia.

The solution includes automatic conveyors complemented with pick to light technology, smart rack, a sorter and integration with the WMS.

As a result of the project, order picking productivity increased by 50%, reaching a capacity of 10,000 orders per day.

SALOG, S.A. (for EsSalud) is a company dedicated to the management of storage, distribution and delivery of materials in the network of warehouses and pharmacies in Lima and Callao, including hospitals, polyclinics, specialized health centers and medical posts of ESSALUD.

IBT HEALTH, S.A.C., a company dedicated to the provision of logistics services, serves 2 hospitals and 2 ESSALUD hospital centers.

Implemented a solution to automate the order picking and sorting process for e-commerce and stores.

The solution includes an automated downward spiral that allows items to be lowered from the upper mezzanine levels, an intelligent order consolidation rack with a Put-to-Wall light-guided system, a Put-to-Store system for store order assembly and a high-performance Sorter for sorting orders by destination.

The solution increased order picking and sorting capacity to 12,000 packages/shift.

A solution was implemented to automate the transport of e-commerce orders.

The installation includes a gravity downward spiral, an automated conveyor belt circuit and a gravity downward spiral for the -1 level.

The solution made it possible to increase the material flow capacity to 300 totes per hour between the different mezzanine and basement levels.

A solution for automated transport of trays (totes) to the order consolidation area was implemented.

The solution included the implementation of a Conveyor that runs the entire length of the warehouse (250 mts. approx.) and will allow the automated transfer of the trays/totes with the items of the picking process from any part of the warehouse to the order consolidation area.

As a result of the project, it is estimated that 65% of the resources dedicated to transporting materials in the warehouse will be reduced.

Automated Pallet Transport Solution (Project in progress).

The solution considers the installation of a Conveyor that will run through 12 of the 16 bays of the Distribution Center to automatically move pallets with items from the bays to the shipping platform, allowing an average movement of 380 to 400 pallets per day.

The conveyor is bi-directional, which allows pallets to be moved from the platform to the bays.

As a result of the project, it is estimated that 75% of the resources dedicated to transporting pallets in the warehouse will be reduced.